WHY IS VRS TECHNOLOGY Superior to other packaging materials?

VRS defines a new era of shielding valuable assets during transport by encasing contents with superior impact and vibration reduction. Independent testing confirms that the lateral and vertical movement of contents surrounded by VRS is controlled, and the majority of any impact/vibration energy is absorbed by the sustainable fill, NOT the cargo.

Infinite Reusability

The VRS system can be reused indefinitely by reconfiguring it for any equipment in any environment. Manufacturing and transportation waste is reduced, saving both time and cost. Whether traveling by air, day use, shipping, or long-term storage, the technology adapts to your needs while fully protecting your assets.

Customization &

Adaptability

One VRS system adapts to any size, weight, and shaped cargo and is limited only by the size of the VRS panel. This offers limitless options for protecting your assets with a single system; no more disposable custom packaging or degrading foam. VRS can be engineered for any panel size and thickness and is compatible with outer casing from aluminum to rigid plastic, cardboard, and wood.

Ultimate Protection

VRS technology incorporates high-tech material loaded with sustainable fill that forms around and safeguards your assets. The system prevents movement and boasts superior vibration reduction and impact protection.

VACUUM RIGIDIZING STRUCTURE

Let KOR® Protect Your Assets

From The Founder:

I had a garage full of hard-sided cases for every shape and size of adventure gear. Each item had a separate case and foam sections to protect my equipment when traveling. Some of the foam was expensively custom cut, several I spent hours meticulously cutting myself, and many more required plucking out little squares to create a space in the shape of each piece of gear.

As my case collection continued to grow, my lovely and observant wife asked me why I needed so many similar cases and why there wasn’t a way for one piece of protective cushioning material to adapt to everything I needed to safely transport my gear. I saw the wisdom of her question and dove into creating a solution. I knew I wasn't the only person who struggled with the limitations and drawbacks of the unchanged foam-filled case offerings we have had for decades. This also made me realize just how costly, storage-space intense, and environmentally wasteful this antiquated solution really was.

With a punch list of inconveniences to resolve, my goal was to produce a universal protection solution and address the disadvantages of the status quo through the following must-haves:

MUST-HAVES

- Deliver protection characteristics superior to foam

- Infinitely reusable, eliminating the need for multiple specific cases

- Quick and easy for anyone to use

- Customizable for a variety of objects

- Must retrofit existing cases

- Cost-effective

- Cleanable and able to be sterilized

- Space saving

- Unlimited lifespan compared to foam

- Reduce waste

- Not impacted by temperature or climate

- Eliminate abrasion on the exterior of cargo

- Lighter weight and more efficient for large cargo transport

THE RESULT

WHAT IS VRS?

Each VRS system consists of a pillow-like panel constructed from MIL-Spec textile and filled with shock absorbing media that when under vacuum, solidly contours to the shape of your object; keeping it firmly positioned and providing superior impact and vibration protection.

VRS panels fit a variety of popular hard-sided cases.

An included syphon pump allows users to quickly and easily add or remove air from the VRS panel so they can customize it for any objects that fit within the existing case.

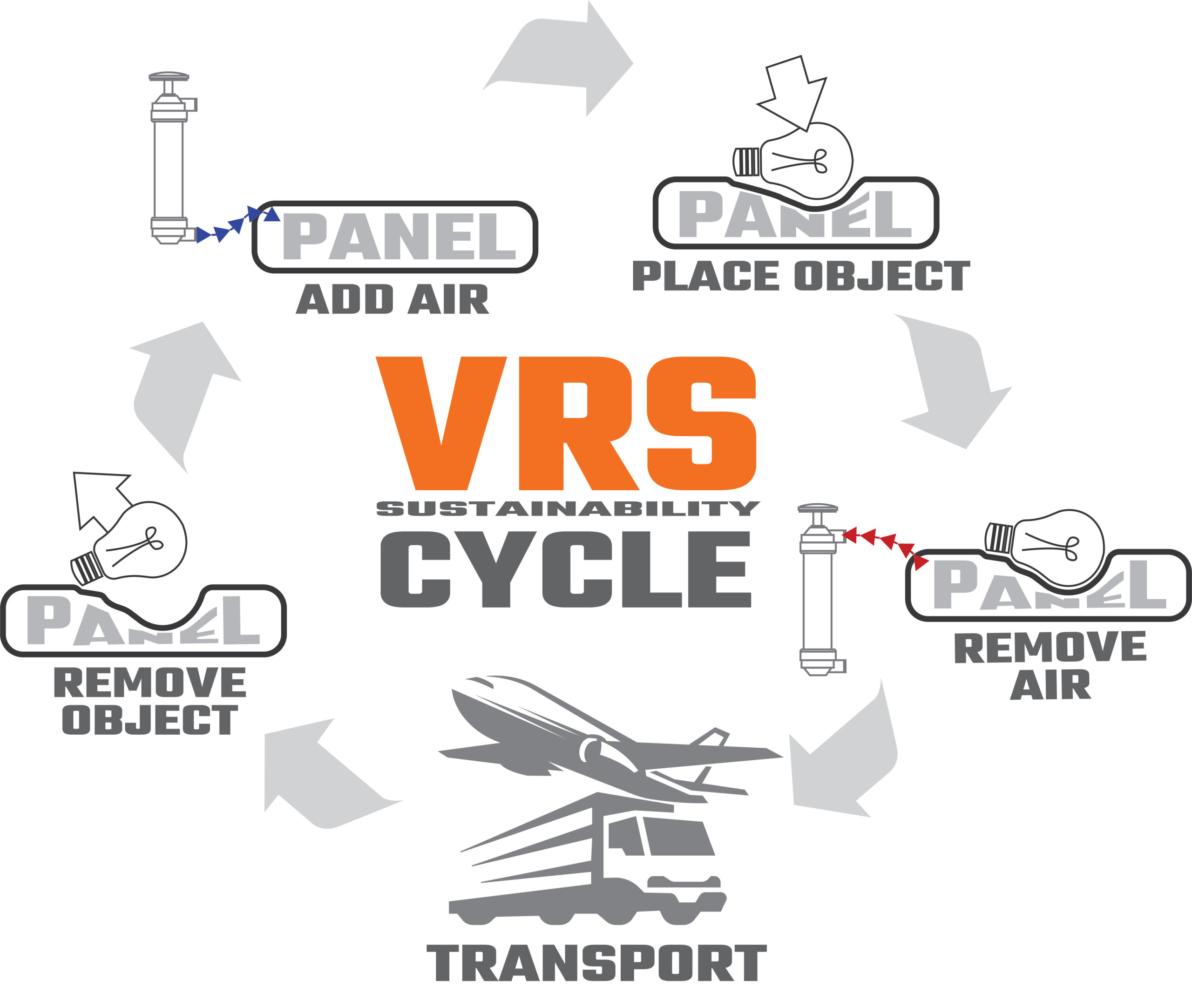

HOW DOES VRS WORK?

Place a VRS panel inside the hard case it is sized for.

When the panel has air inside, it is soft and pliable, like a cushion or bean bag (fluid state).

Nestle contents into panel, and when air is removed (vacuumed) with the pump, the VRS panel conforms around the items creating a solid impression (rigid state).

To use the VRS panel for a different object, pump air into the panel, replace the item, and pump (pull vacuum) until the panel conforms to the new object.

Thank you for your time, your business, and supporting my family and employees. -- GP

Join our newsletter